Object Detection in Industrial Inspections

Home » Case Study » Object Detection in Industrial Inspections

Project Overview:

Objective

The “Image Annotation for Retail Inventory Management” project aims to create a dataset for training machine learning models, specifically focusing on object detection. Consequently, these models will accurately annotate and classify retail products and items in images. This dataset will enhance the efficiency and accuracy of retail inventory management, thus leading to improved stock tracking, demand forecasting, and shelf optimization.

Scope

This project involves collecting images of retail products from various sources, including retail stores, e-commerce platforms, and manufacturer databases. Additionally, annotating them with relevant product information is crucial.

Project Overview:

Objective

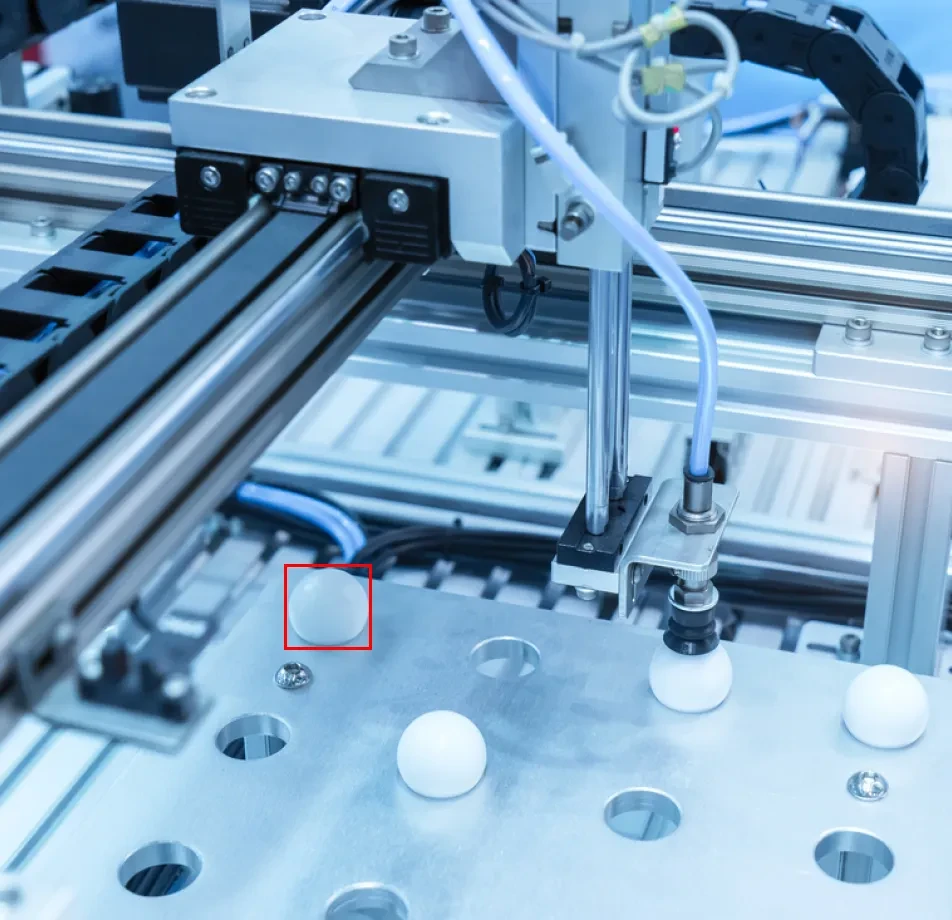

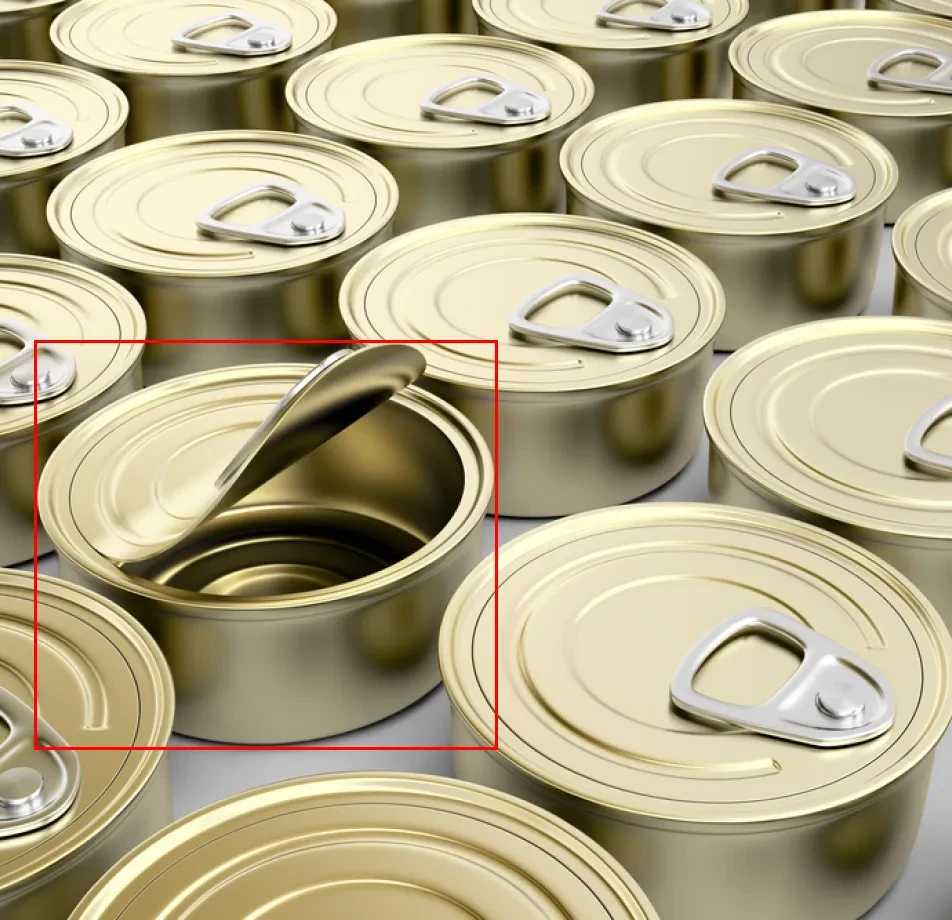

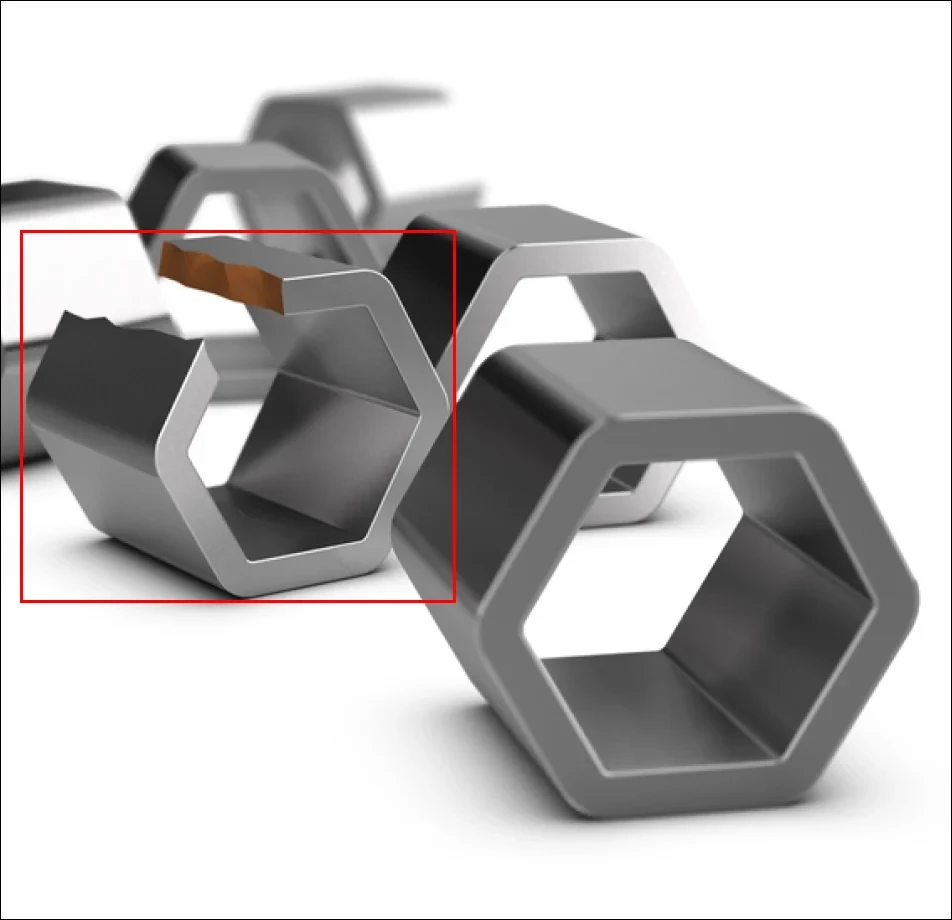

Our goal was to curate a robust dataset to fuel an advanced object detection system. This system is designed to transform how industries detect defects in machinery and product lines, boosting both efficiency and accuracy.

Scope

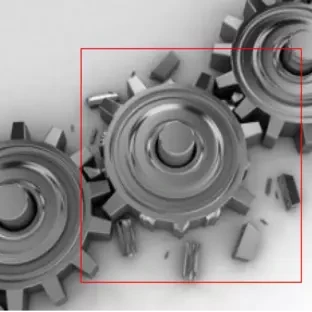

We embarked on an ambitious journey to design and amass a machine learning dataset. This dataset focuses on identifying anomalies and manufacturing defects in industrial settings, using high-resolution images of machinery and equipment.

Sources

- Industrial Collaborations: We partnered with various industries to gather over 150,000 high-resolution images of machinery and products. Additionally, we collaborated closely with these industries to ensure comprehensive coverage. Moreover, our efforts included engaging with experts to capture nuanced details. Furthermore, we meticulously curated each image to maintain quality standards.

- Simulated Scenarios: We supplemented our collection with 10,000 annotated images from public databases, thereby ensuring a comprehensive dataset.

- Public Resources: We supplemented our collection with 10,000 annotated images from public databases, thereby ensuring a comprehensive dataset.

Data Collection Metrics

- Total Images: 200,000

- From Industrial Partnerships: 150,000

- Simulated Environment: 40,000

- Public Databases: 10,000

Annotation Process

Stages

- Defect Identification: We marked defects with precise bounding boxes, categorizing them into various categories like cracks, rust, and deformities. Additionally, we analyzed each defect thoroughly to ensure accurate classification.

- Contextual Metadata: Each image was enriched with details such as machinery type and inspection date, thereby offering valuable context.

- Severity Assessment: We assigned a severity score to each defect, thereby aiding in prioritized maintenance decisions.

Annotation Metrics

- Images with Defect Annotations: 200,000

- Logged: 200,000

- Severity Ratings Assigned: 200,000

Quality Assurance

Stages

Continuous Model Evaluation: Regularly monitoring the model’s performance and retraining it with new data is crucial to maintaining high accuracy.

Privacy Protocols:Ensure that no sensitive company or proprietary data is included in the dataset. Additionally, all images used for training should be generic and devoid of specific brand markings.

Feedback Mechanism: Enable on-ground industrial inspectors to provide feedback on model detections, thereby ensuring the model remains relevant and effective. Consequently, this feedback loop fosters continuous improvement, allowing for timely adjustments and enhancements to the detection system. Moreover, by incorporating real-world insights from inspectors, the model can adapt to evolving challenges and scenarios in industrial environments.

QA Metrics

- Model Accuracy on Test Data: 98.5%

- Detection Speed: 25 ms per frame

- False Positive Rate: 0.5%

Conclusion

The implementation of the object detection system for industrial inspections has revolutionized the way industries maintain quality and machinery health. The AI-driven approach not only enhances accuracy but also speeds up the inspection process, ensuring minimal downtime and maximum operational efficiency.

Quality Data Creation

Guaranteed TAT

ISO 9001:2015, ISO/IEC 27001:2013 Certified

HIPAA Compliance

GDPR Compliance

Compliance and Security

Let's Discuss your Data collection Requirement With Us

To get a detailed estimation of requirements please reach us.