Machine Part Defects Segmentation Dataset

Home » Case Study » Machine Part Defects Segmentation Dataset

Project Overview:

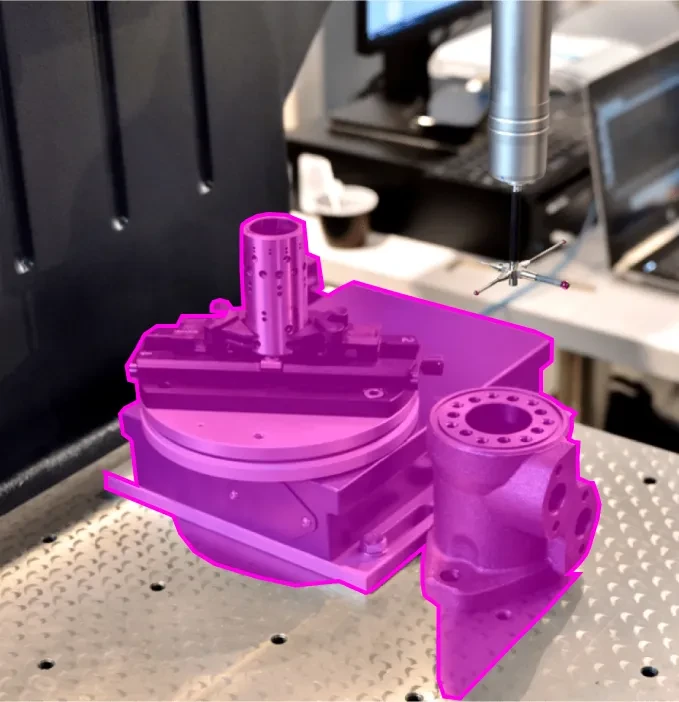

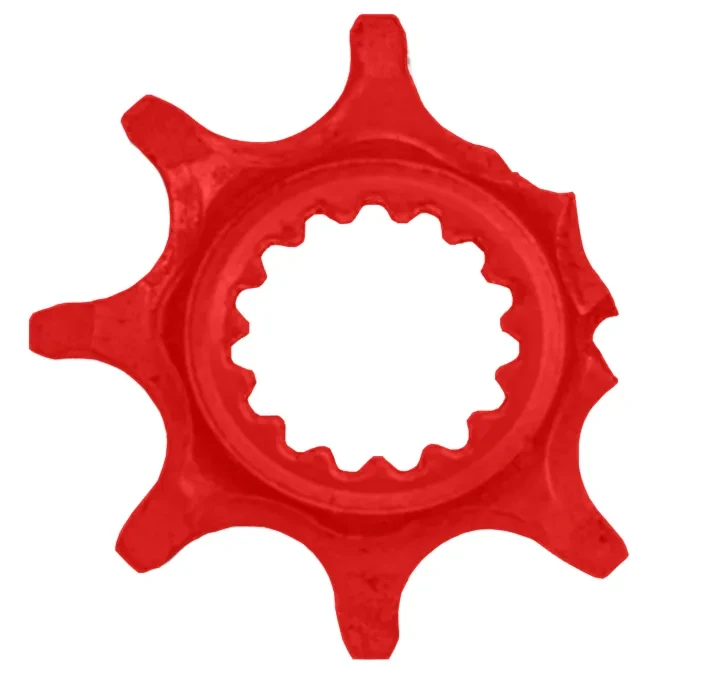

Objective

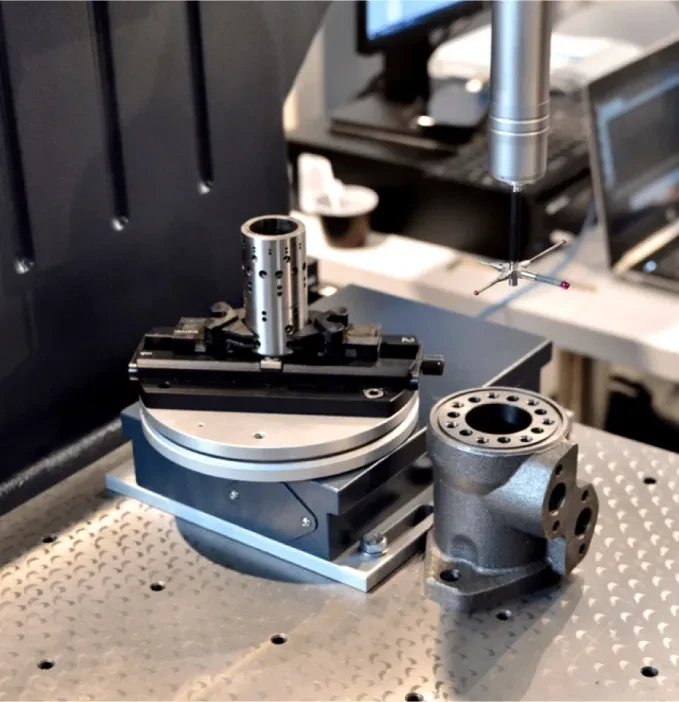

As a leading data collection and annotation firm, we recently completed a significant project aimed at enhancing automated quality control and maintenance in manufacturing. Our objective was to construct a dataset that segments defects in machine parts within images, aiding in the development of cutting-edge machine learning models for industrial applications.

Scope

Our team successfully built an extensive image repository, which includes a variety of machine parts. Each image features meticulously annotated segmentation, highlighting defects and anomalies, vital for machine learning applications in quality control, maintenance, and manufacturing processes.

Sources

- Manufacturing Facilities: Collaborate with industrial manufacturing plants to obtain images captured during quality control inspections.

- Quality Control Records: Extract images from historical quality control records, which often contain documentation of defective parts.

- Public Submissions: Develop a platform for individuals to contribute images of machine parts with known defects, promoting diversity in defect types and machine parts.

Data Collection Metrics

- Total Images Collected and Annotated: 175,000

- Manufacturing Facility Contributions: 95,000

- Quality Control Records Extracts: 45,000

- Public Submissions: 35,000

Annotation Process

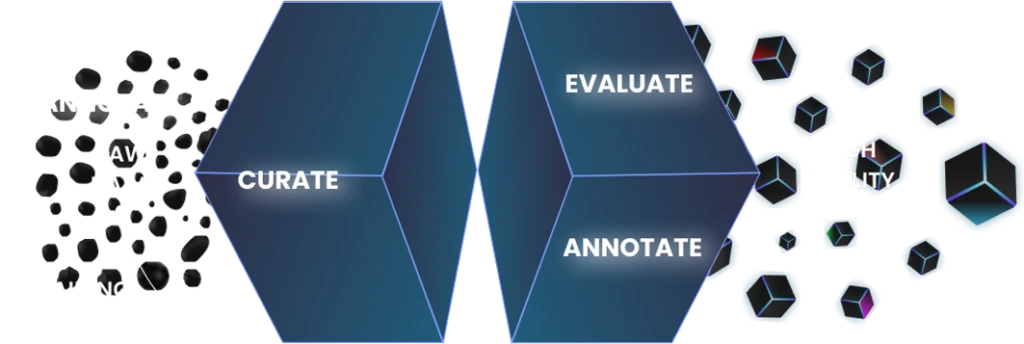

Stages

- Defect Segmentation: We annotated each image to precisely define the defect boundaries.

- Machine Part Identification: Each image was labeled with detailed information about the machine part.

- Defect Type Categorization: We categorized the defects into various types, such as cracks and corrosion.

- Severity Level Assignment: A severity level was tagged to each defect, indicating its impact on machine performance.

Annotation Metrics

- Images with Defect Segmentations: 175,000

- Machine Part Identifications: 175,000

- Defect Type Labels: 175,000

- Severity Level Tags: 175,000

Quality Assurance

Stages

Segmentation Accuracy Checks: We used advanced computer vision algorithms, supported by domain experts, to ensure segmentation accuracy.

Metadata Validation: Quality control specialists and industrial engineers verified the accuracy of machine part identification and defect categorization.

Privacy Safeguards: We implemented strict controls to protect the privacy of publicly contributed images, ensuring no sensitive or proprietary information was included.

QA Metrics

- Segmentation Validation Cases: 17,500

- Metadata Authentication Reviews: 26,250

- Privacy Audits: 35,000

Conclusion

Through the Machine Part Defects Segmentation Dataset Initiative, our company has established a vital resource for the industrial sector. Our comprehensive and accurately annotated dataset is instrumental in developing machine-learning models that streamline defect detection and enhance manufacturing efficiency.

Quality Data Creation

Guaranteed TAT

ISO 9001:2015, ISO/IEC 27001:2013 Certified

HIPAA Compliance

GDPR Compliance

Compliance and Security

Let's Discuss your Data collection Requirement With Us

To get a detailed estimation of requirements please reach us.