Anomaly Detection in Manufacturing Processes

Home » Case Study » Anomaly Detection in Manufacturing Processes

Project Overview:

Objective

The objective of this project is to develop a dataset and machine learning models for detecting anomalies in manufacturing processes. Anomaly detection is critical in manufacturing to identify deviations from standard operations that could lead to defects or inefficiencies, ultimately improving product quality and process efficiency.

Scope

This case study showcases our expertise in data collection and annotation in the manufacturing sector. We demonstrate our capacity to gather and refine data that is pivotal for training models to detect anomalies, a crucial step in advancing manufacturing precision and reliability.

Sources

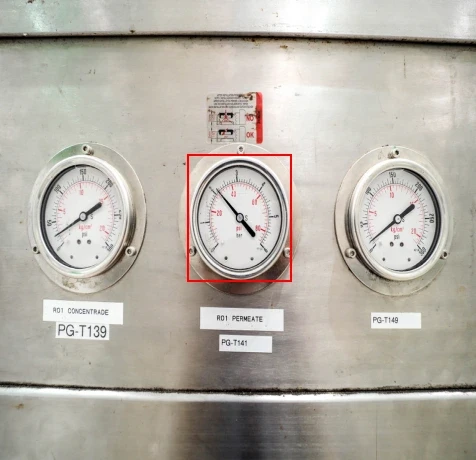

- Sensors and Instrumentation: Collaborate with manufacturing facilities to access sensor data that measures variables like temperature, pressure, and machine performance.

- Cameras and Visual Data: Install cameras on the production line to capture visual data for monitoring and detecting anomalies in product appearance or machinery.

- Equipment Logs: Extract data from equipment logs and maintenance records to monitor the health and performance of manufacturing machinery.

Data Collection Metrics

- Total Data Points: 100,000

- Sensor Data: 60,000

- Visual Data: 30,000

- Equipment Logs: 10,000

Annotation Process

Stages

- Anomaly Labeling: Annotate data points to indicate whether they represent normal or anomalous manufacturing conditions.

- Timestamp and Equipment ID: Log metadata, including timestamps and equipment identifiers, to track the timing and source of anomalies.

- Anomaly Severity: Assign a severity rating to each anomaly to prioritize maintenance or intervention.

Annotation Metrics

- Data Points with Anomaly Labels: 100,000

- Timestamp and Equipment ID Metadata: 100,000

- Anomaly Severity Ratings: 100,000

Quality Assurance

Stages

Annotation Verification:Implement a validation process involving domain experts to review and verify the accuracy of anomaly labels.

Privacy Compliance:Ensure compliance with privacy regulations, especially when using visual data. Anonymize any personally identifiable information.

Data Security:Implement robust data security measures to protect sensitive manufacturing information and maintain data integrity.

QA Metrics

- Annotation Validation Cases: 10,000 (10% of total)

- Ongoing privacy audits to ensure compliance

Conclusion

The “Anomaly Detection in Manufacturing Processes” project is pivotal for enhancing manufacturing efficiency and product quality. By harnessing diverse data sources, accurate anomaly annotations, and rigorous privacy and security measures, this initiative empowers the development of advanced anomaly detection models. These models will help manufacturers proactively identify and address anomalies, leading to improved production processes and cost savings.

Quality Data Creation

Guaranteed TAT

ISO 9001:2015, ISO/IEC 27001:2013 Certified

HIPAA Compliance

GDPR Compliance

Compliance and Security

Let's Discuss your Data collection Requirement With Us

To get a detailed estimation of requirements please reach us.